Stainless steel straightening machines are indispensable tools for the manufacturing industry. They are used to straighten and flatten various metal products, including ceiling plates. Ceiling plates are an essential component in the construction industry, as they provide a smooth and aesthetically pleasing finish to the ceiling of a building. However, during the manufacturing process, these plates may become bent or warped, making them unsuitable for use. This is where stainless steel straightening machines come in.

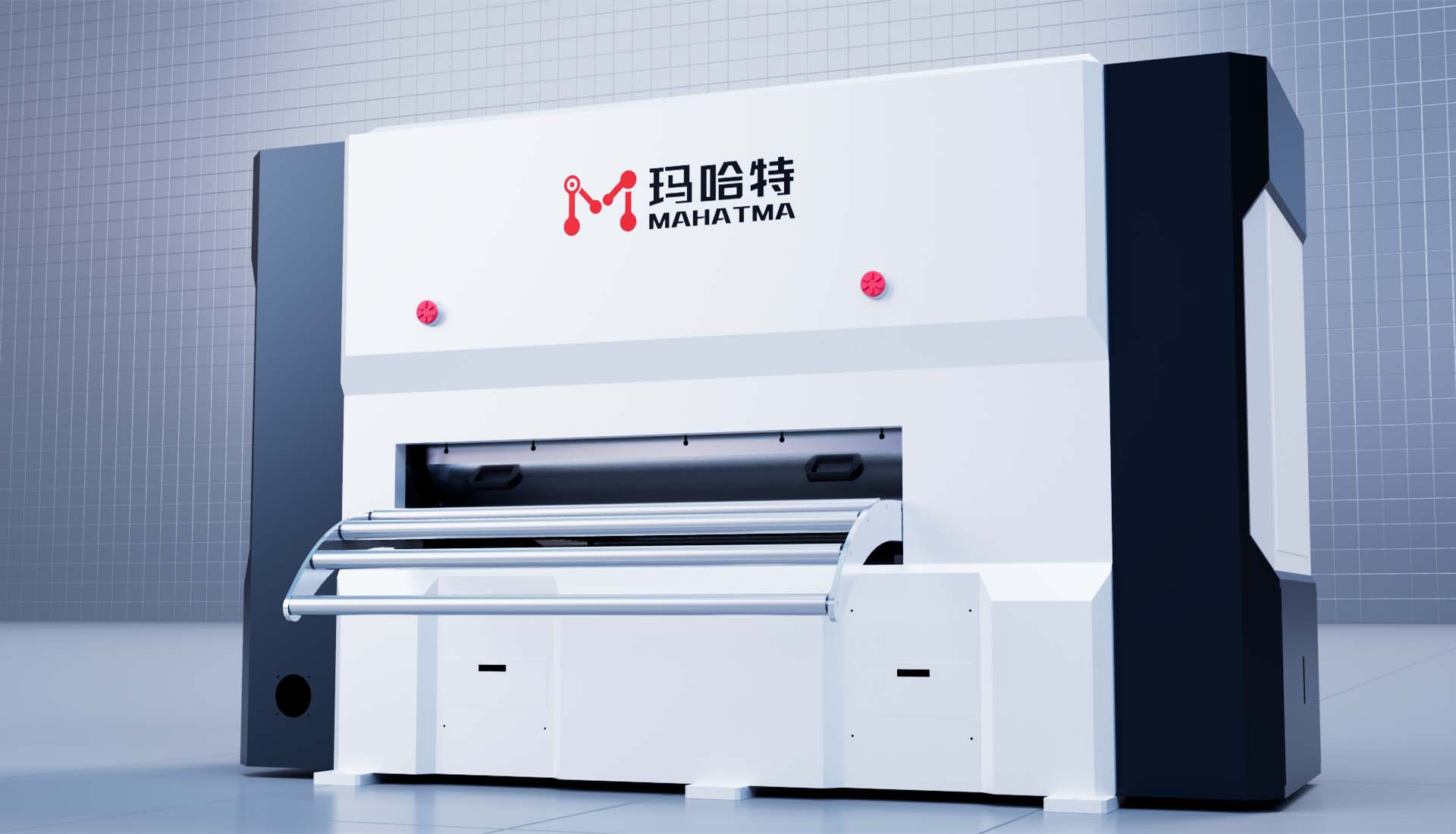

A stainless steel straightening machine uses a variety of techniques to straighten and flatten metal products, including hydraulic pressure, heat treatment, and mechanical rollers. These machines are designed to work with various types of metals, including stainless steel, aluminum, and copper.

When it comes to straightening ceiling plates, a stainless steel straightening machine is a crucial tool. Ceiling plates are typically made from thin sheets of stainless steel, which are prone to warping and bending during the manufacturing process. This can be caused by a variety of factors, including improper handling, temperature changes, and stress from cutting or punching.

A stainless steel straightening machine can help to correct these issues by applying the appropriate amount of pressure to the metal. This pressure can be adjusted to suit the thickness and type of metal being straightened, ensuring that the metal is not damaged or weakened in the process.

One of the key benefits of using a stainless steel straightening machine for ceiling plates is that it can help to improve the quality and consistency of the finished product. By straightening the metal, the plates will be more uniform in shape and size, making them easier to work with during installation. This can help to save time and reduce waste, as fewer plates will need to be discarded due to imperfections.

Another advantage of using a stainless steel straightening machine for ceiling plates is that it can help to reduce costs. When plates become warped or bent during the manufacturing process, they may need to be discarded, which can be a significant expense. By using a straightening machine, these plates can be salvaged and used, reducing the need to purchase new materials.

Stainless steel straightening machines are available in a range of sizes and configurations, making them suitable for use in a variety of settings. Some machines are designed for use in large-scale manufacturing facilities, while others are more compact and can be used in smaller workshops or garages.

When choosing a stainless steel straightening machine for ceiling plates, it is important to consider a range of factors. These include the size and thickness of the plates being straightened, the type of metal being used, and the level of precision required. It is also important to choose a machine that is easy to operate and maintain, as this can help to ensure that it remains in good working order for years to come.

In conclusion, a stainless steel straightening machine is an essential tool for the manufacturing industry, particularly when it comes to straightening and flattening ceiling plates. By using a straightening machine, manufacturers can improve the quality and consistency of their products, reduce waste and costs, and increase efficiency. With so many benefits on offer, it is no wonder that stainless steel straightening machines are becoming increasingly popular in the construction industry.