Straightening machines for sheet metal are essential tools in the metalworking industry. They are used to correct the deformations and imperfections that occur during the manufacturing process. These machines are designed to straighten and flatten sheets of metal, ensuring they meet precise specifications and quality standards.

Sheet metal is widely used in various industries, including automotive, construction, and manufacturing. It is a versatile material that can be formed into different shapes and sizes. However, during the fabrication process, sheets of metal can become distorted or bent due to factors such as rolling, cutting, or welding.

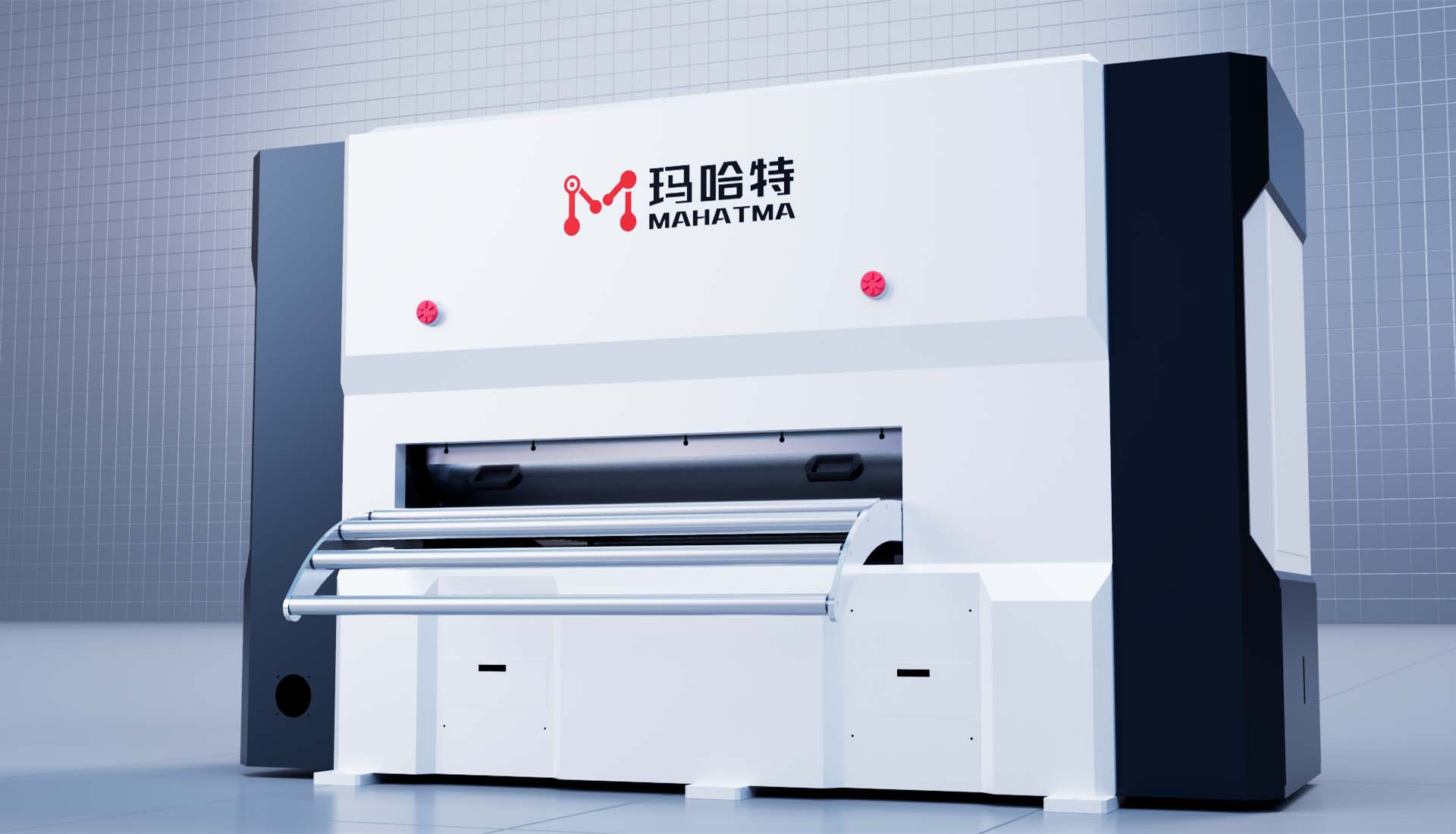

Straightening machines are specifically designed to address these issues. They use a combination of pressure and force to straighten the metal and restore its original shape. These machines are equipped with adjustable rollers or hydraulic systems that apply pressure to the sheet metal, gradually straightening it out.

One of the key features of straightening machines is their ability to handle different types of sheet metal. They can be used on a wide range of materials, including steel, aluminum, copper, and stainless steel. This versatility makes them indispensable in various applications where straight and flat metal sheets are required.

Straightening machines come in different sizes and configurations to accommodate different sheet sizes and thicknesses. Some machines are designed for smaller sheets, while others are capable of handling larger and heavier materials. The choice of machine depends on the specific needs and requirements of the metalworking project.

These machines are also equipped with safety features to ensure the operator's well-being. Emergency stop buttons, safety guards, and interlocking systems are integrated into the machines to prevent accidents and injuries. Additionally, operators are provided with proper training on how to operate the machine safely and efficiently.

Straightening machines offer several advantages over manual straightening methods. They provide consistent and accurate results, eliminating human error and ensuring the quality of the final product. These machines are also time-saving, as they can straighten large quantities of sheet metal in a short amount of time.

Moreover, straightening machines are cost-effective in the long run. By preventing waste and rework, they help minimize material and labor costs. They also contribute to the overall efficiency of the production process, increasing productivity and reducing downtime.

Straightening machines are essential tools in the metalworking industry. They play a crucial role in correcting deformations and imperfections in sheet metal, ensuring the production of high-quality and precise products. These machines offer numerous benefits, including versatility, safety, accuracy, and cost-effectiveness. Whether used in automotive manufacturing, construction, or any other industry that utilizes sheet metal, straightening machines are indispensable in achieving optimal results.