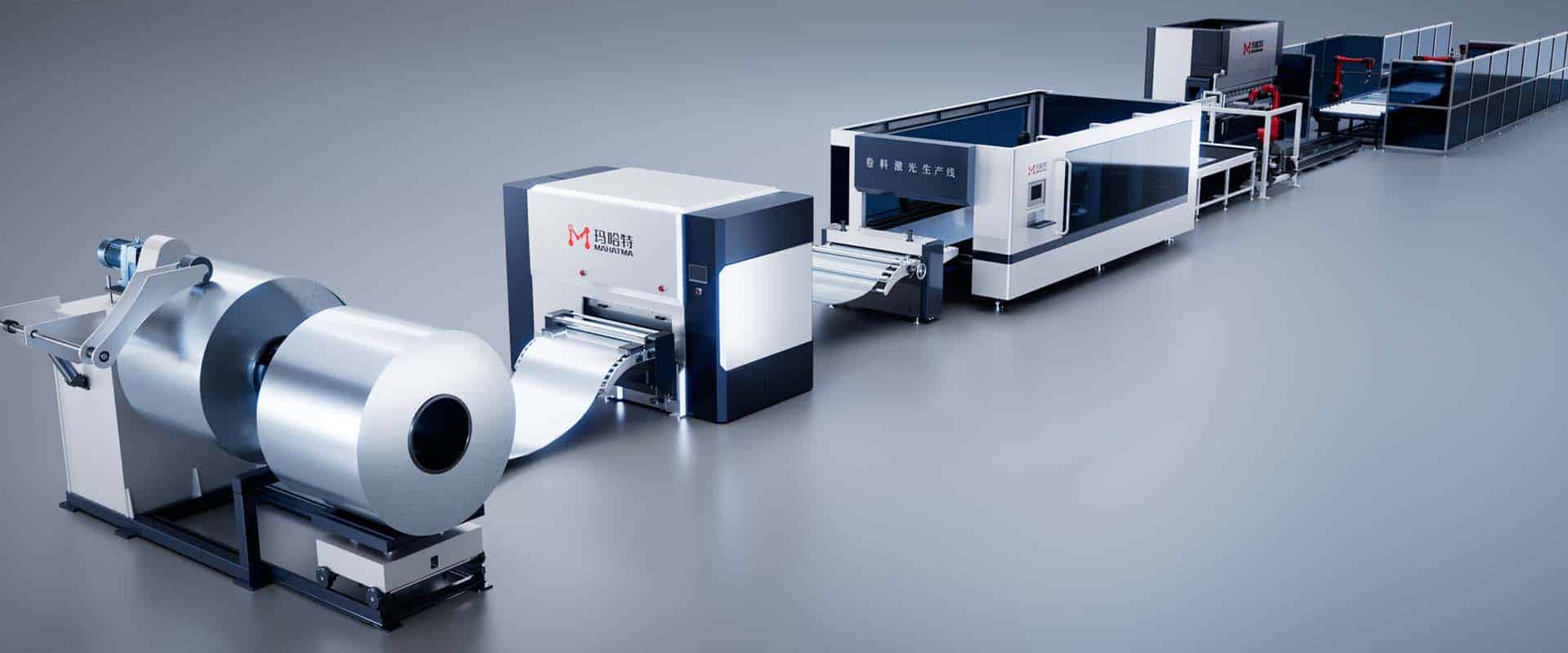

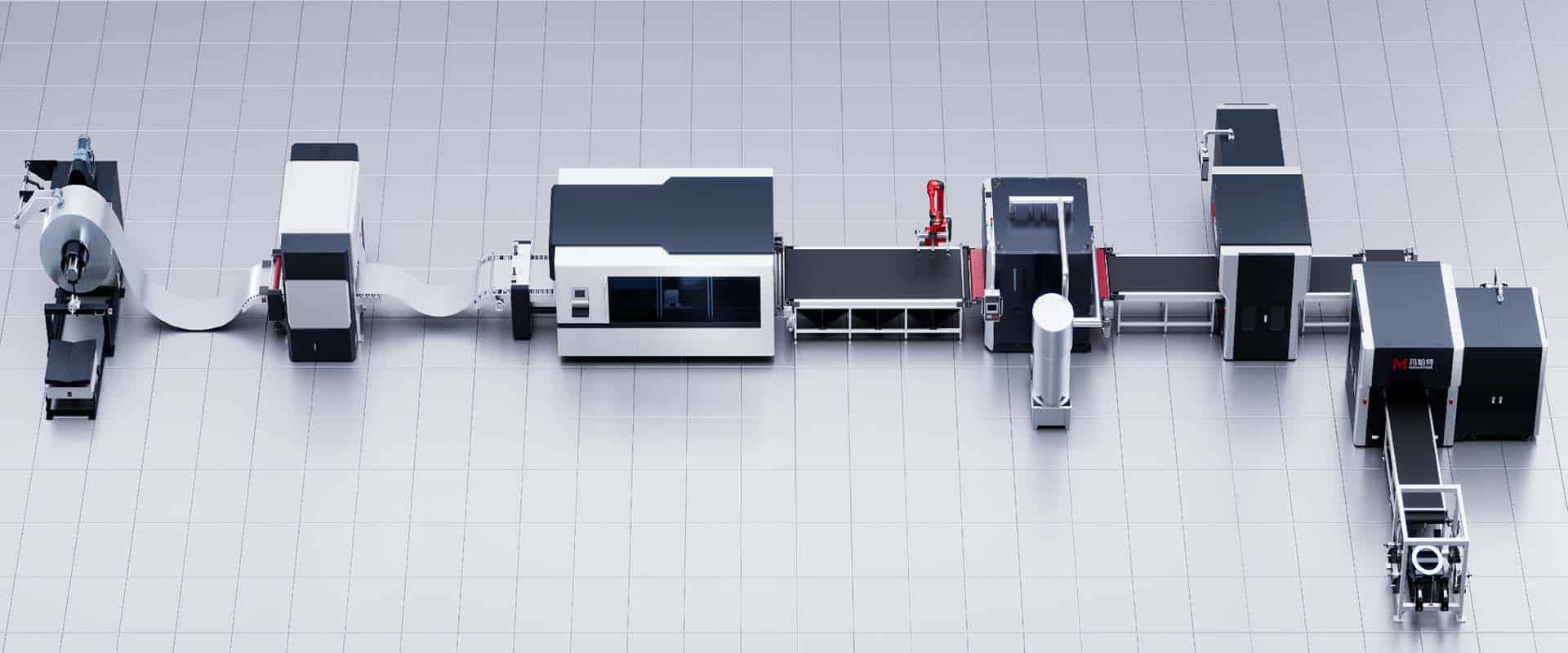

MAHATMA is a well-known maker of sheet metal leveling machines. They make a variety of high-precision tools that are meant to get the best flatness and accuracy when working with metal. The next section talks about the most important features and product lines of Mahatma’s sheet metal levelers:

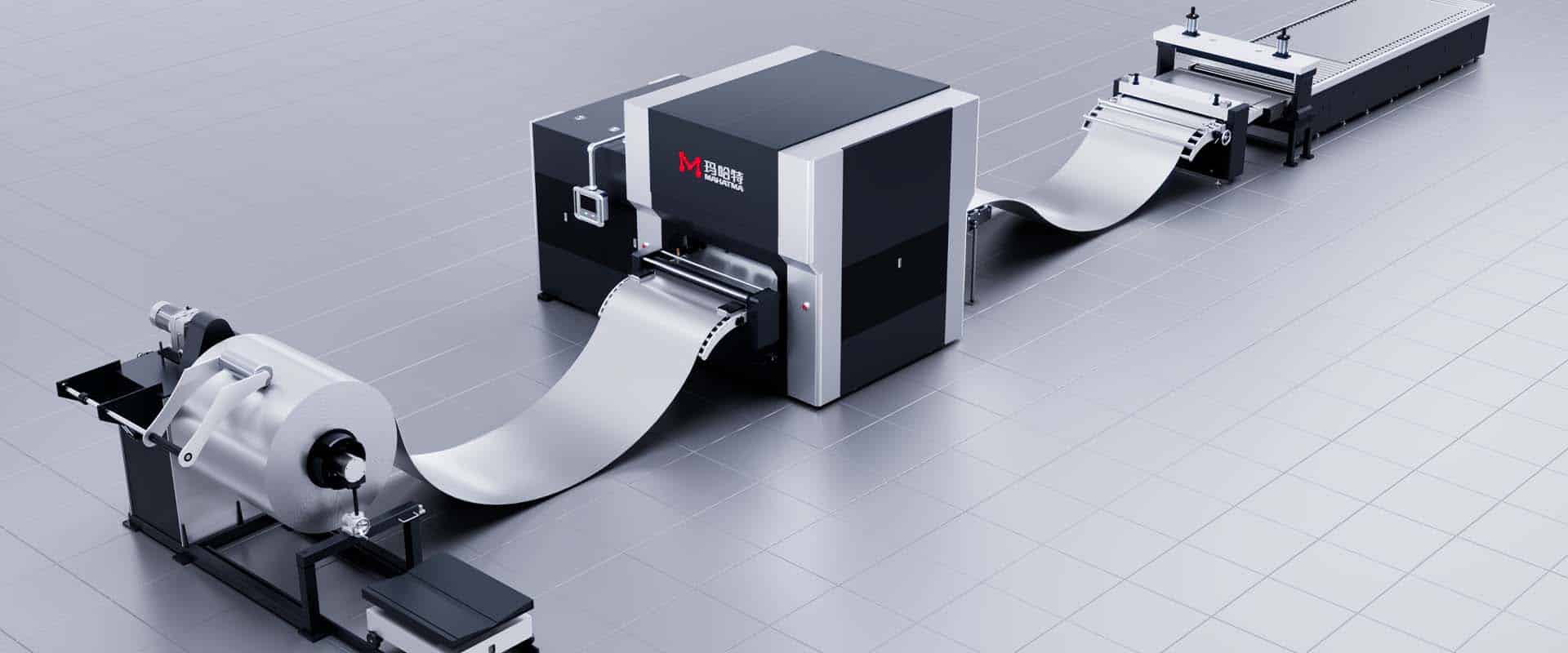

Features of the Servo Hydraulic Ultra-Thick Plate High-Precision Leveling Machine:

Hydraulic pressure: Keeps the gap between the upper and lower leveling rollers the same, which keeps the correction even for a lot of parts.

10-inch High-Precision Touch Screen: A programmable logic controller (PLC) with visual input, editing, changing, and storing process parameters controls the machine.

Rapid Flattening: This method can flatten stampings, sheets, and parts in just a few minutes with very little stress.

Precision Leveling: It uses a set of rollers to bend the metal sheet over and over again, changing the amount of bending so that the sheet’s appearance doesn’t get damaged.

Harmonic Attenuation: The multi-layer roller structure makes sure that the force is evenly distributed and the rigidity is high, which stops any rolling marks.

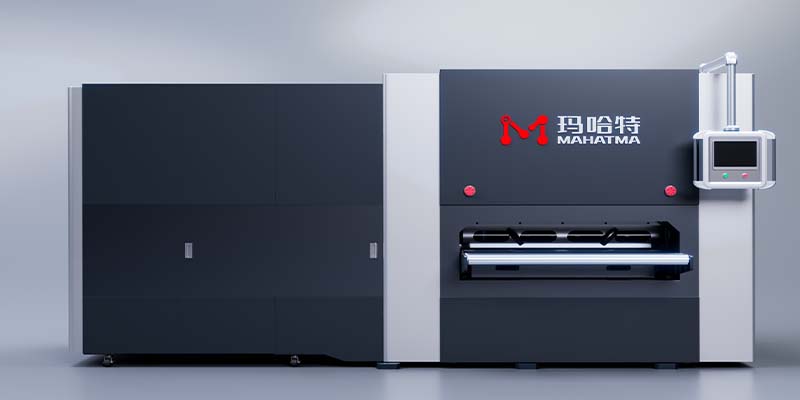

CNC Precision Leveling Machine has the following features:

Bauschinger Effect: Uses the material’s “Bauschinger effect” to bend the plate over and over again, slowly lowering the bending deflection until the plate is flat.

High-Precision Control: The motor and programmable logic controller (PLC) work together to carefully set the pressure on each leveling drum, which reduces internal stresses and makes sure that leveling is as accurate as possible.

The machine has a simple interface that makes it easy to use. Adding a 10-inch high-precision touch screen display with PLC control makes it easy to enter, edit, and save process parameters.

Efficient Operation: The machine can level high-precision and complicated hardware in just a few seconds, which cuts down on the time it takes to level by hand by a lot.

The CNC Precision Leveling Machine in the MHT50 Series has the following features:

Multiple Bending: It uses the “Bauschinger effect” to bend the metal sheet over and over again, slowly lowering the bending deflection until it is perfectly flat.

High-Precision Control: PLC control makes sure that the leveling rollers are set exactly right, which gets rid of internal stresses and makes sure that the leveling is very accurate.

The machine also has an interface that is easy to use. The PLC-controlled 10-inch high-precision touch screen display makes it easy to enter, change, and store process parameters.

Quick Flattening: The machine can flatten stampings, sheets, and parts in just a few minutes with very little stress.

Important Performance FeaturesStrong hydraulic pressure keeps the gap between leveling rollers the same, which keeps the correction even for a lot of parts.

High-Precision Touch Screen: The 10-inch high-precision touch screen with PLC control makes it easy to enter, change, and save process parameters.

The rapid flattening process is a big plus because it lets you flatten stampings, sheets, and parts quickly and with little stress. It can flatten stampings, sheets, and parts in just a few minutes with very little stress.

Precision Leveling: It uses a series of rollers that bend the metal sheet over and over again, changing the amount of bending to keep the sheet from getting damaged.

Harmonic Attenuation: The multi-layer roller structure makes sure that the force is spread evenly and the roller is very stiff, so there are no rolling marks.

UsesMahatma’s sheet metal leveling machines are used in a lot of different industries, such as:

Vehicle Manufacturing: These machines are used to flatten and fix metal sheets that are used to make the bodies of cars and trucks.

For flattening metal sheets used in construction and architecture, the building industry.

Medical Technology: This is used to make sure that metal sheets used in medical equipment are perfectly level.

5G Communications: This technology is used to flatten and fix metal sheets that are used in 5G infrastructure.

Electronics and Appliances: The main purpose of this technology is to flatten metal sheets that are used to make electronic and appliance goods.

The business started in 2002. It is in the city of Dongguan in the province of Guangdong in China.

The business is a high-tech one. The company is well-known for its leveling tools and other devices that work with them.

Research and Development: The company focuses its research and development on CNC leveling machines, hydraulic leveling machines, and quadruple leveling machines.

The company’s customers include well-known businesses in a wide range of fields, such as 5G communications, cabin cabinets, auto and motorcycle parts, transportation, aerospace, sheet metal processing, electric power, building materials, and ceiling curtain walls. The company works with well-known businesses in a variety of fields, including cabin cabinets, auto and motorcycle accessories, transportation, aerospace, sheet metal processing, electric power, building materials, ceiling curtain walls, and 5G communications.

MAHATMA is a top maker of sheet metal leveling machines because it is dedicated to quality and innovation. Its machines are very accurate and can be used for many different things.