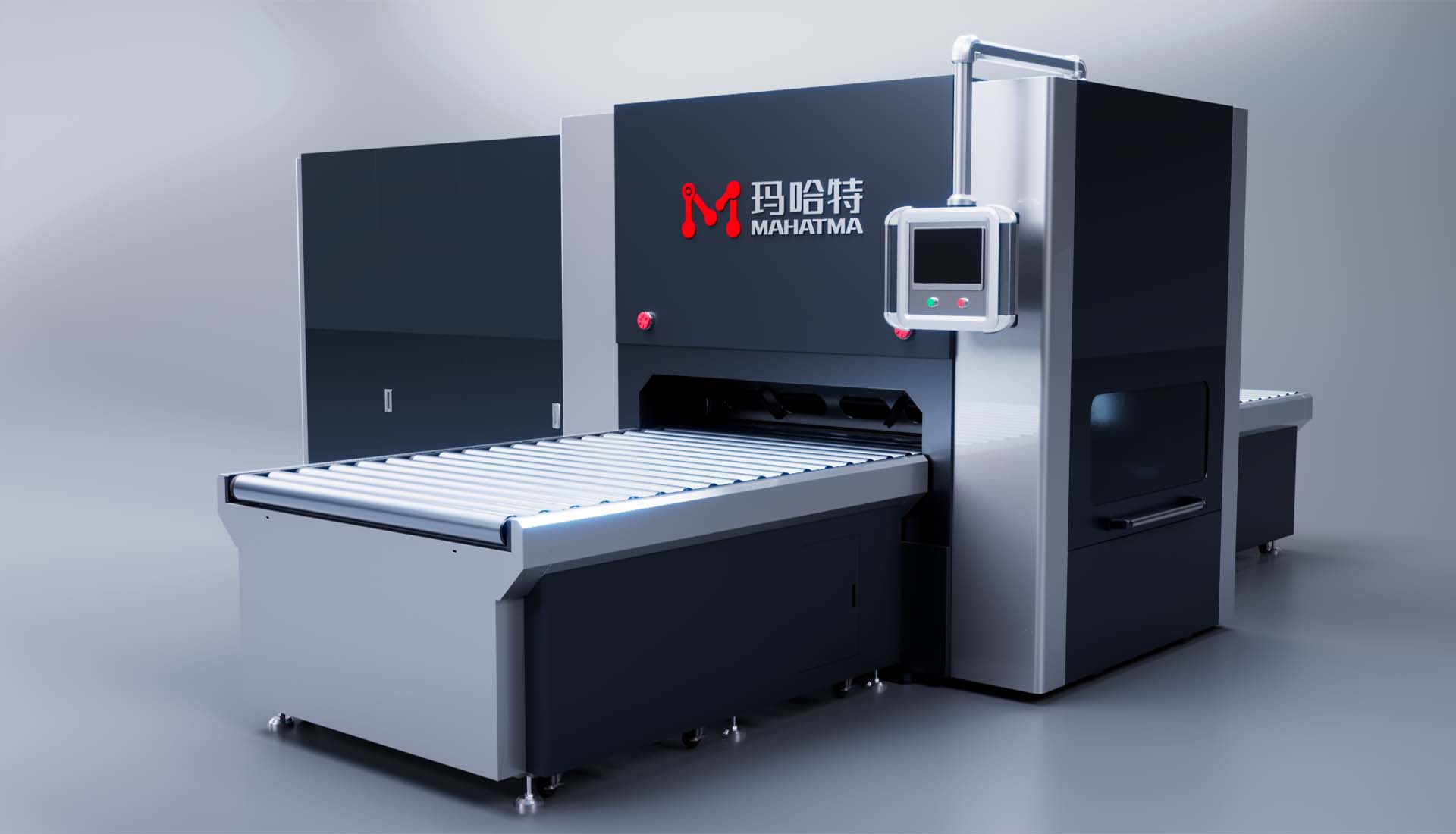

Full automation CNC precision leveler is a highly advanced and sophisticated machine that is designed to level and flatten metal sheets with unmatched precision and accuracy. This machine operates using computer numerical control (CNC) technology, which allows for complete automation of the leveling process, eliminating the need for manual intervention.

The full automation CNC precision leveler is a versatile machine that can handle a variety of metal sheets, including steel, aluminum, and stainless steel. It is capable of processing sheets of different thicknesses, ranging from 0.5 mm to 25 mm. This machine is commonly used in various industries, such as automotive, construction, and metal fabrication, where flat and level metal sheets are required.

One of the main advantages of the full automation CNC precision leveler is its ability to produce high-quality, flat, and level metal sheets consistently. The machine uses a series of precision rollers that apply pressure to the metal sheet, flattening it to the desired level. The CNC technology ensures that the rollers apply the correct amount of pressure to each section of the metal sheet, resulting in a uniformly flat surface.

In addition to its precision and accuracy, the full automation CNC precision leveler is also known for its speed and efficiency. The machine can process large quantities of metal sheets in a short amount of time, which makes it ideal for high-volume production environments.

The full automation CNC precision leveler is also equipped with advanced features that enhance its performance and efficiency. For example, the machine is equipped with sensors that detect any irregularities in the metal sheet, such as waves or wrinkles. The sensors send signals to the CNC system, which adjusts the pressure of the rollers to correct the irregularities, ensuring that the metal sheet is perfectly flat.

Another feature of the full automation CNC precision leveler is its ability to store and recall leveling parameters. This means that the machine can save the leveling parameters for each type of metal sheet, thickness, and processing speed. When the machine is set up to process a specific metal sheet, it automatically recalls the appropriate leveling parameters, eliminating the need for manual adjustments.

The full automation CNC precision leveler is also designed with operator safety in mind. The machine is equipped with safety features such as emergency stop buttons, safety guards, and interlocks that prevent the machine from operating if any safety devices are not in place.

In conclusion, the full automation CNC precision leveler is a highly advanced and sophisticated machine that has revolutionized the metal sheet leveling process. It offers unparalleled precision, accuracy, speed, and efficiency, making it an ideal choice for high-volume production environments. Its advanced features and safety measures ensure that it is both reliable and safe to operate. With the full automation CNC precision leveler, manufacturers can produce high-quality, flat, and level metal sheets consistently, which is essential for many industries.