1. Fuse: when mechanical overload or failure occurs, the fuse will be blown off. In this case, replace the fuse after troubleshooting.

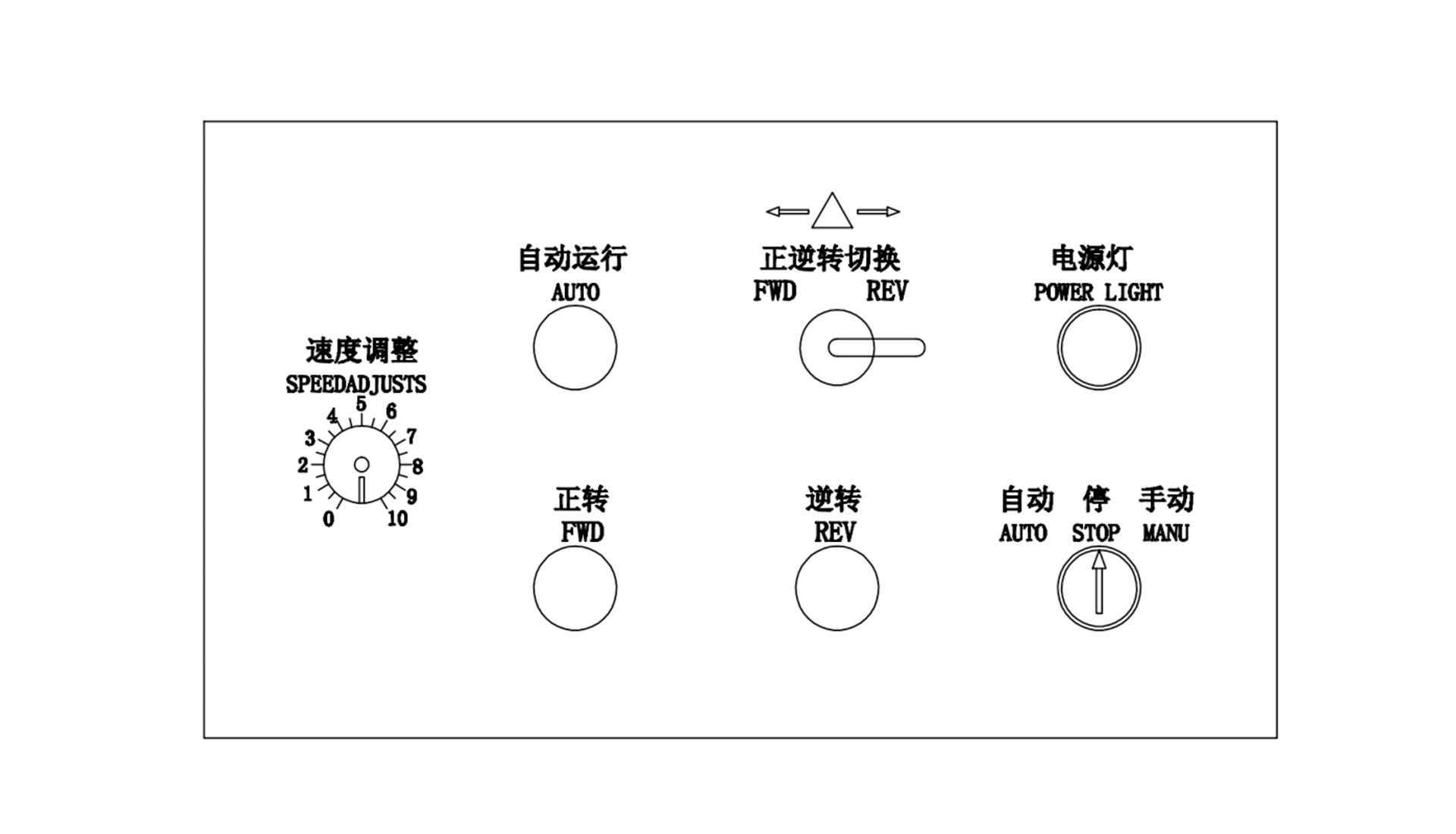

2. Power light: This light is on when the power switch is switched to "on".

3. Automatic operation: The light is on when this button is selected.

4. Forward; When the straightener is in manual state, press this button and the straightener will turn forward.

5. Reverse: When the leveler is in manual state, press this button to reverse the leveler.

6. Automatic/stop/manual: when the switch is dialed to "automatic", the straightening machine will run automatically according to the induction device; At this point "positive turn".

7. Or "reverse" is invalid. When the switch is dialed to "manual", the straightening machine will run according to "forward" and "reverse" Settings, and when dialed to "stop", the straightening machine will stop action.

How to operate the machien to level workpieces

Step 1: measure material thickness and plane distortion

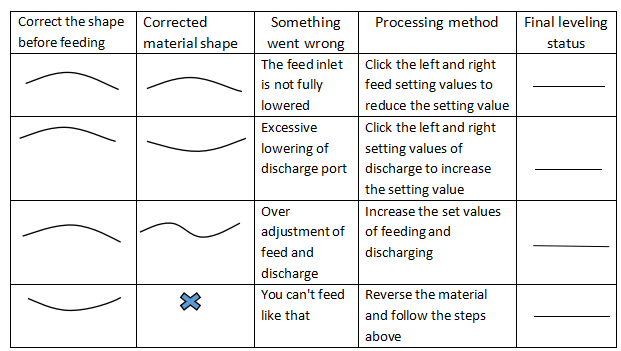

Step 2: put the leveler in and out, and then adjust the leveler(if the materials are put into the leveler with loose inlet and outlet, the hand wheel shall be adjusted downward until there is resistance. If the materials are put into the leveler with tight inlet and outlet, the hand wheel shall be adjusted upward until there is resistance.)

Step 3: adjust accurately according to the leveling operation of tightening before loosening.(when there is resistance in and out of the material, adjust the inlet downward by 1mm and the outlet does not move)

Step 4: turn on the power and turn on the automatic mode

Step 5: put the material into the leveling machine for leveling

Step 6: check the flatness of the material and put the material on the marble platform for testing.(if the material is put into the leveling machine and leveling is ineffective, adjust it according to step 7)

Step 7: precision leveling again(if the leveling effect has not been achieved, continue to adjust the inlet downward by 1mm. If the front pressure is too high, adjust the outlet downward and level it)

Step 8: check the flatness of materials to achieve the effect

Step 9: complete the commissioning, turn off the power, and clean the interior and surface of the machine