Large levelling machines, also known as levellers, are a type of equipment used in the metalworking industry to flatten and level metal sheets and plates. These machines are designed to remove any surface irregularities or deformations from the metal surface, resulting in a perfectly flat and smooth finish. Levelling machines are commonly used in the production of high-quality metal products, such as automotive parts, electrical enclosures, and appliances.

Levelling machines come in different sizes and configurations, depending on the application and the size of the metal sheets or plates being processed. Large levelling machines are typically used for heavy-duty applications, where thick and wide metal sheets or plates need to be levelled and flattened. These machines are designed to handle large volumes of metal, making them ideal for high-volume production environments.

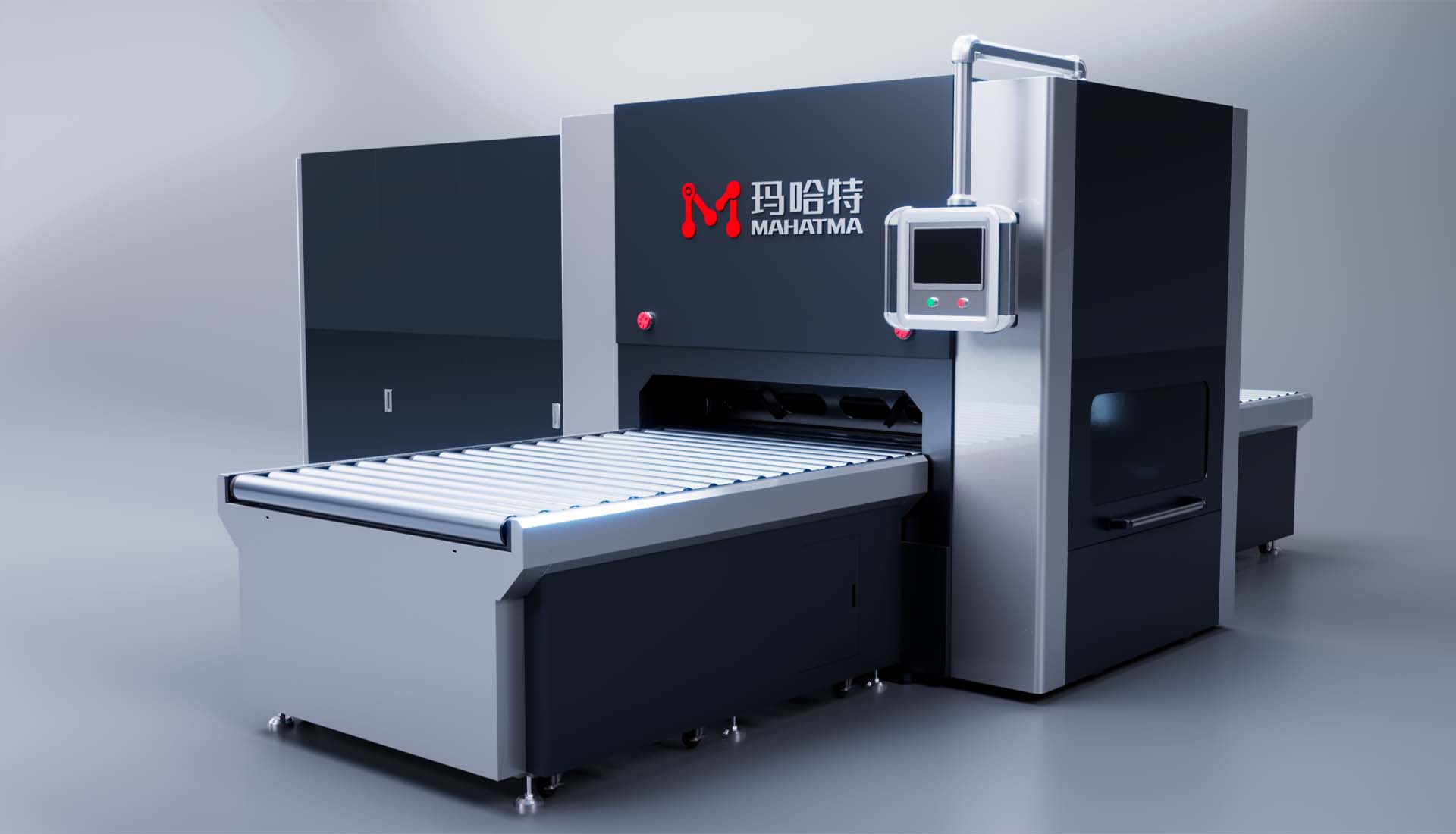

Large levelling machines are made up of several components, including a frame, a roller system, and a hydraulic system. The frame is the main structure of the machine, and it provides support for the roller system. The roller system is made up of a series of hardened steel rollers that are arranged in a specific pattern to ensure that the metal sheet or plate is levelled and flattened evenly. The hydraulic system is used to control the pressure and speed of the rollers, allowing the operator to adjust the machine to suit the specific requirements of the metal being processed.

One of the main advantages of large levelling machines is their ability to process a wide range of metals, including steel, aluminum, copper, and brass. These machines can handle metal sheets and plates of varying thicknesses and widths, making them ideal for a variety of applications. Large levelling machines are also very efficient, with some models capable of processing several thousand sheets or plates per hour. This efficiency makes them ideal for high-volume production environments, where speed and accuracy are essential.

Another advantage of large levelling machines is their ability to produce high-quality finishes. The even and consistent pressure applied by the rollers ensures that the metal surface is levelled and flattened evenly, resulting in a smooth and uniform finish. This makes large levelling machines ideal for applications where a high-quality finish is required, such as automotive parts, electrical enclosures, and appliances.

Large levelling machines are also very easy to operate, with most models featuring user-friendly controls that allow the operator to adjust the machine to suit the specific requirements of the metal being processed. The hydraulic system is controlled using a series of buttons or a touchscreen interface, allowing the operator to adjust the pressure and speed of the rollers with ease. This makes large levelling machines ideal for use in production environments where operators may not have extensive technical knowledge or experience.

In addition to their many advantages, there are also some considerations to keep in mind when using large levelling machines. One of the main considerations is safety, as these machines can be very powerful and can pose a risk to operators if not used properly. It is important to ensure that operators are properly trained and that all safety protocols are followed to minimize the risk of accidents or injuries.

Another consideration is maintenance, as large levelling machines require regular maintenance to ensure that they continue to operate efficiently and effectively. This includes regular cleaning and lubrication of the rollers, as well as regular inspection of the hydraulic system to ensure that it is functioning properly. It is important to follow the manufacturer's recommended maintenance schedule to ensure that the machine remains in good working order and to minimize the risk of breakdowns or other issues.

Large levelling machines are an essential piece of equipment in the metalworking industry, particularly in high-volume production environments where speed and accuracy are essential. These machines are designed to level and flatten metal sheets and plates of varying thicknesses and widths, producing high-quality finishes that are ideal for a variety of applications. While there are some considerations to keep in mind when using large levelling machines, such as safety and maintenance, the many advantages of these machines make them an indispensable tool for any metalworking operation.