Plate levellers are essential tools used in various industries to ensure optimal precision and stability in the alignment of machine components. These devices play a crucial role in maintaining accurate measurements and preventing potential errors that could lead to costly damages or inefficiencies.

The primary purpose of a plate leveller is to level or align plates, which are large, flat surfaces that form the foundation of many machines. These plates are typically made of metal and are crucial for supporting heavy equipment, such as industrial machinery, engines, or turbines. Therefore, it is vital to ensure that these plates are perfectly level to guarantee smooth operation and prevent any adverse effects on the machine's performance.

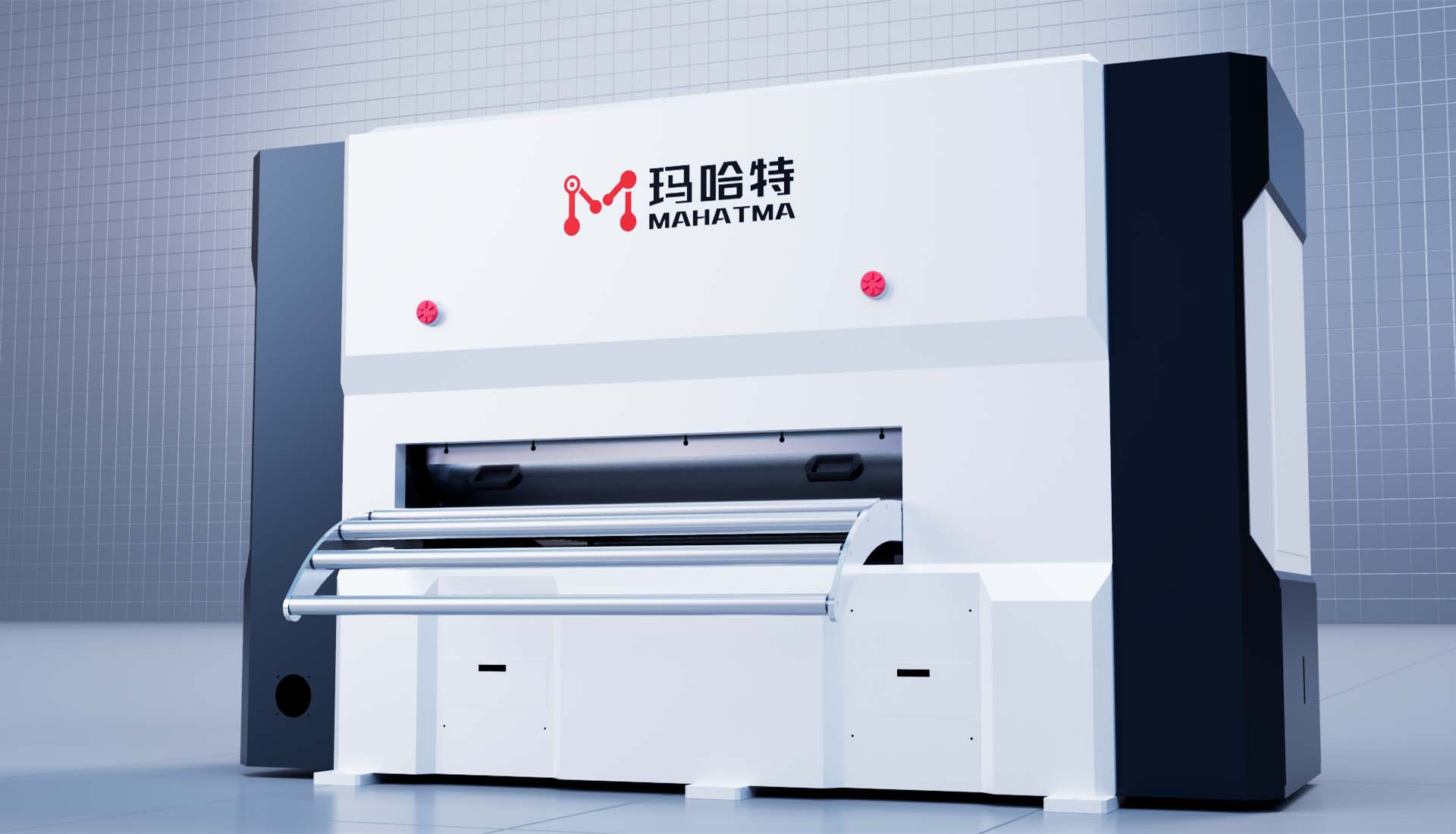

Plate levellers typically consist of several key components, including a base, a leveling plate, and an adjustable mechanism. The base provides stability and support, while the leveling plate is responsible for ensuring the plate's alignment. The adjustable mechanism allows the user to make precise adjustments to achieve the desired level of accuracy.

To use a plate leveller, it is crucial to follow a systematic approach. First, the leveller is placed on the surface of the plate, ensuring that it covers the entire area that needs to be leveled. The user then adjusts the leveling plate using the adjustable mechanism to bring it into contact with the plate's surface. By carefully manipulating the adjustable mechanism, the leveller enables the user to raise or lower specific areas of the plate until it reaches the desired level.

One significant advantage of using a plate leveller is its ability to ensure uniform weight distribution across the plate's surface. Uneven weight distribution can lead to excessive stress on specific areas, resulting in premature wear and tear or even structural damage. By leveling the plate, the leveller helps distribute the load evenly, reducing the risk of such issues.

Furthermore, plate levellers are often used in conjunction with other measuring tools, such as digital levels or laser alignment systems, to achieve an even higher level of precision. These additional tools provide real-time feedback and measurements, allowing the user to make accurate adjustments based on the leveller's readings.

Plate levellers find applications in various industries, including manufacturing, construction, automotive, and aerospace. In the manufacturing industry, plate levellers play a vital role in ensuring the accuracy and stability of production machinery, guaranteeing consistent quality and minimizing defects. In construction, plate levellers are used to align foundation plates, ensuring the stability and integrity of structures. The automotive and aerospace industries utilize plate levellers during the assembly and alignment of engine components, ensuring optimal performance and reducing the risk of malfunctions.

Plate levellers are indispensable tools for achieving precise alignment and stability in various industries. These devices enable users to level large, flat surfaces, ensuring uniform weight distribution and minimizing the risk of errors or damages. By using plate levellers, industries can maintain optimal performance, reduce downtime, and enhance overall productivity.