Roller straightening is a process of straightening metal sheets or coils by passing them through a series of rollers. The rollers apply pressure to the metal, which helps to eliminate any curvature or waviness in the material. This process is commonly used in the manufacturing of metal products, such as automotive parts, construction materials, and household appliances.

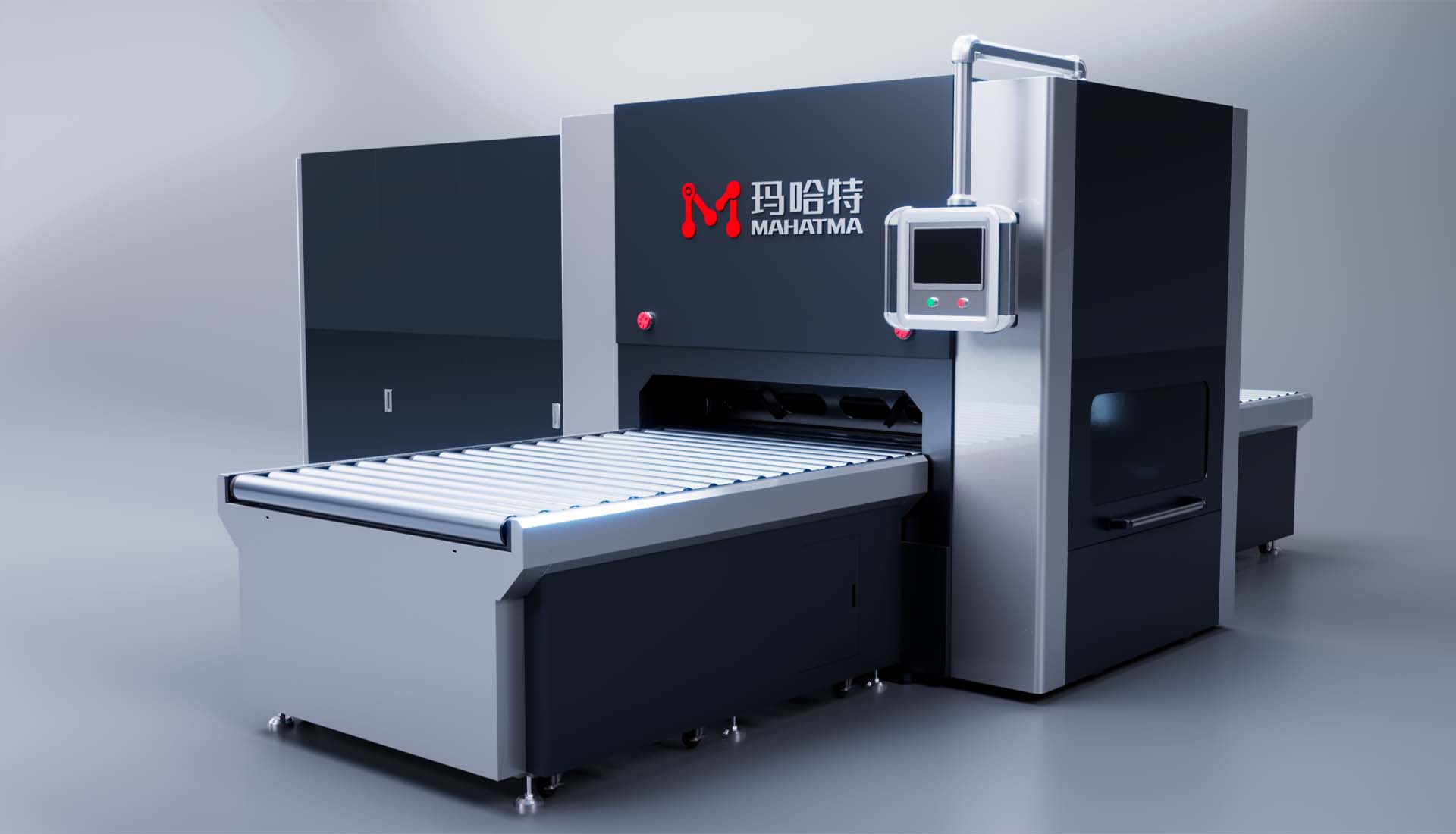

Roller straightening machines, also known as roller levelers or roller flatteners, are specialized equipment that are designed to perform this task. These machines consist of a series of rollers that are arranged in a specific pattern to achieve the desired level of straightening. The rollers can be adjusted to apply different amounts of pressure to the material, which allows for precise control over the straightening process.

The roller straightening process starts with feeding the metal sheet or coil into the machine. The rollers then grip the material and begin to pull it through the machine. As the material passes through the rollers, it is subjected to a series of bending and unbending forces that help to straighten it. The rollers can be adjusted to apply more or less pressure to the material, depending on the degree of straightening required.

There are several advantages to using roller straightening machines. One of the main benefits is that they can straighten large sheets or coils of metal quickly and efficiently. This can save time and labor costs, as well as improve the overall quality of the finished product. Roller straightening machines are also highly accurate and can be adjusted to achieve very precise levels of straightening.

Another advantage of roller straightening is that it can be used to straighten a variety of different materials, including steel, aluminum, copper, and brass. This makes it a versatile process that can be used in a wide range of industries.

Roller straightening machines come in a variety of sizes and configurations, depending on the specific needs of the application. Some machines are designed for use in small-scale manufacturing, while others are designed for use in large-scale industrial settings. The size and complexity of the machine will depend on the size and thickness of the material being straightened, as well as the desired level of straightening.

One of the key features of roller straightening machines is their ability to handle a wide range of thicknesses and widths of material. This makes them ideal for use in the production of a variety of different products, from thin sheet metal to thick steel plates.

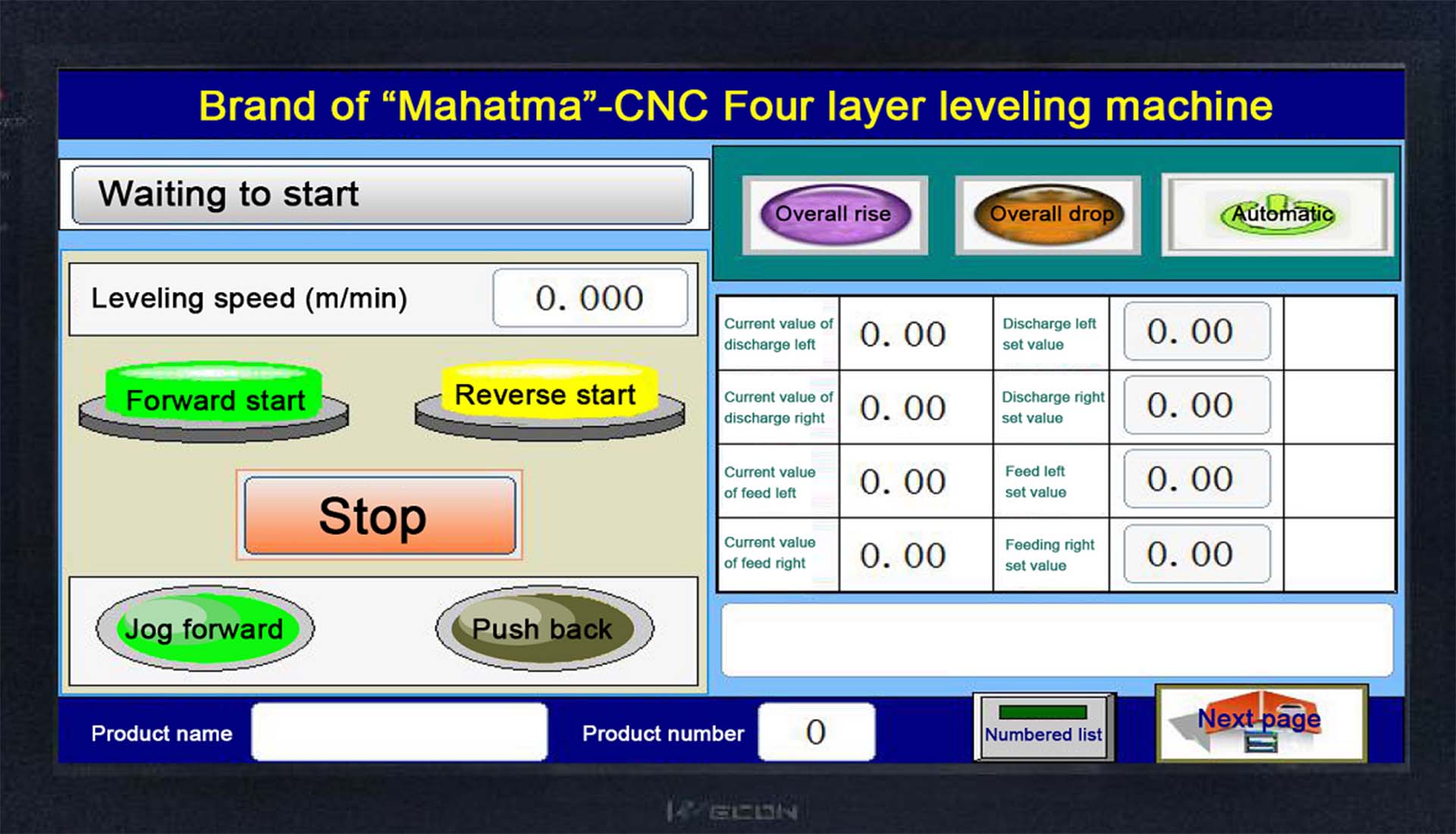

Roller straightening machines can also be equipped with a variety of different accessories, such as sensors and gauges, that help to ensure accurate and consistent straightening. These accessories can provide real-time feedback on the performance of the machine, allowing operators to make adjustments as needed to achieve the desired level of straightening.

In addition to their use in manufacturing, roller straightening machines can also be used for metal processing and recycling. Scrap metal that has become bent or warped can be straightened using these machines, helping to increase the value of the material and reduce waste.

Overall, roller straightening is a highly effective process for straightening metal sheets and coils. It offers several advantages over other methods of straightening, including speed, accuracy, and versatility. Roller straightening machines are an essential tool for many industries, and their use is likely to continue to grow in the future.