Laser cutting is a high-precision, high-efficiency metal processing method. It can quickly cut metal materials into various shapes and has a wide range of applications. However, during the laser cutting process, due to the influence of thermal stress, sometimes the cutting parts will warp. This warping not only affects the appearance and precision of the cut piece, but also affects its mechanical properties, so mechanical leveling is required.

Mechanical leveling is a processing method that mechanically corrects a deformed material into a plane. For metal materials that warp after laser cutting, mechanical leveling is a common correction method. Mechanical leveling can be carried out in a variety of ways. Two commonly used mechanical leveling methods are introduced below.

The first is mechanical leveling by heating. This method is suitable for some metal materials, and the internal stress distribution can be changed by heating, thereby reducing or eliminating warpage. The specific method is to heat the warped cutting piece to a certain temperature, place it on a flat workbench, and then perform mechanical leveling. During the leveling process, attention should be paid to the control of the heating temperature and the selection of the heat source to avoid deformation or damage of the material due to overheating.

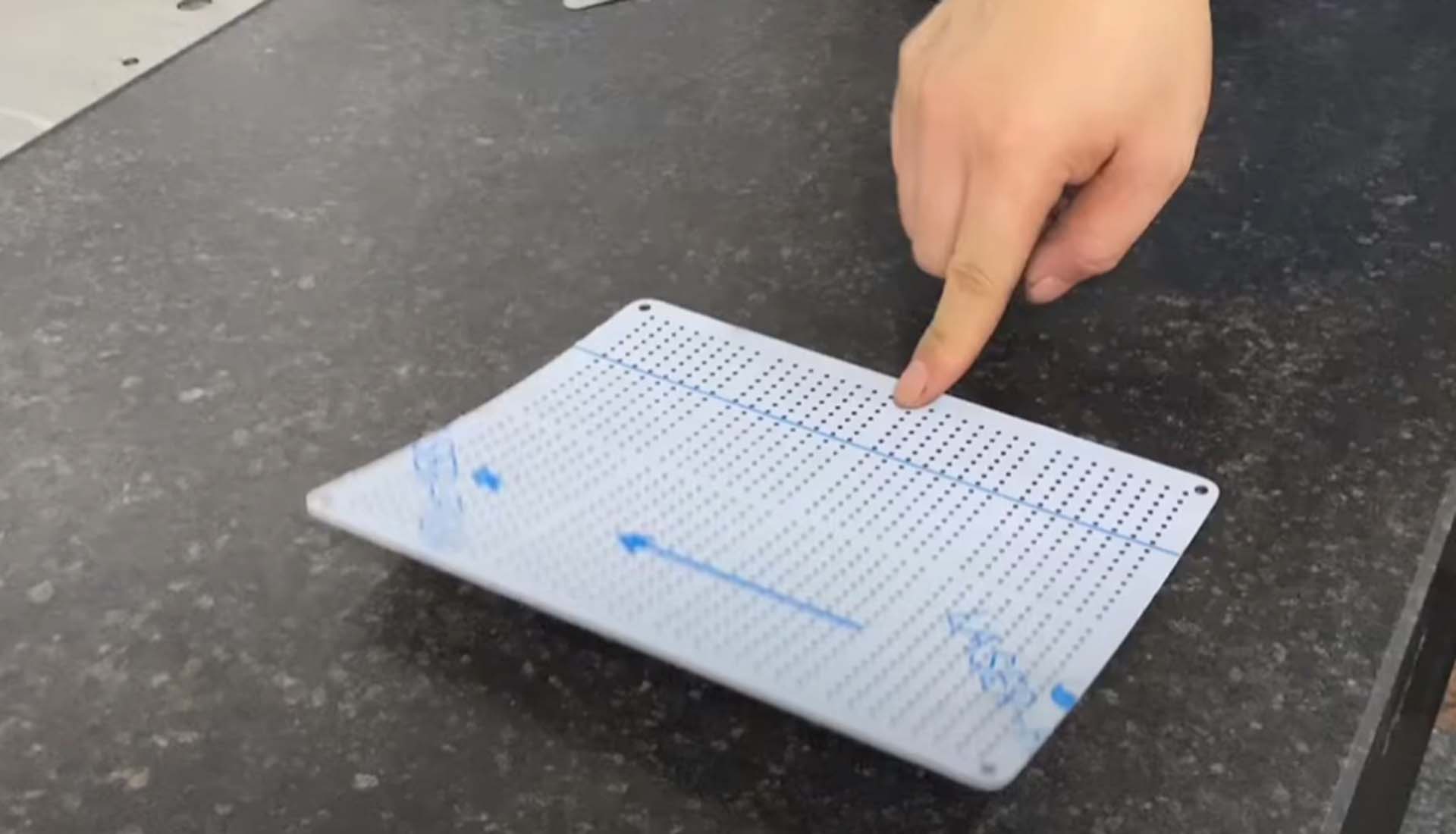

The second is mechanical leveling by mechanical pressure. This method is suitable for some harder metal materials, and the warped part can be flattened by mechanical pressure, so that it can be restored to flatness. The specific method is to place the warped cutting piece on the platen, and then apply appropriate pressure to level it. During the leveling process, attention should be paid to the control of pressure and the speed of leveling to avoid damage to the material due to excessive pressure.

Mechanical leveling is an effective method to solve the problem of warping after laser cutting. When performing mechanical leveling, it is necessary to select an appropriate leveling method according to the characteristics of the material and the degree of warping to ensure the leveling effect and the performance of the material.