High precision aluminum plate CNC machining is a cutting-edge manufacturing process that utilizes computer numerical control (CNC) technology to produce high-quality aluminum plates with exceptional precision. This advanced machining technique has revolutionized the way aluminum plates are produced, offering numerous advantages over traditional manufacturing methods.

Aluminum plates are widely used in various industries due to their excellent properties, such as lightweight, corrosion resistance, and high strength-to-weight ratio. However, achieving high precision in the production of aluminum plates has always been a challenge. This is where CNC machining comes into play.

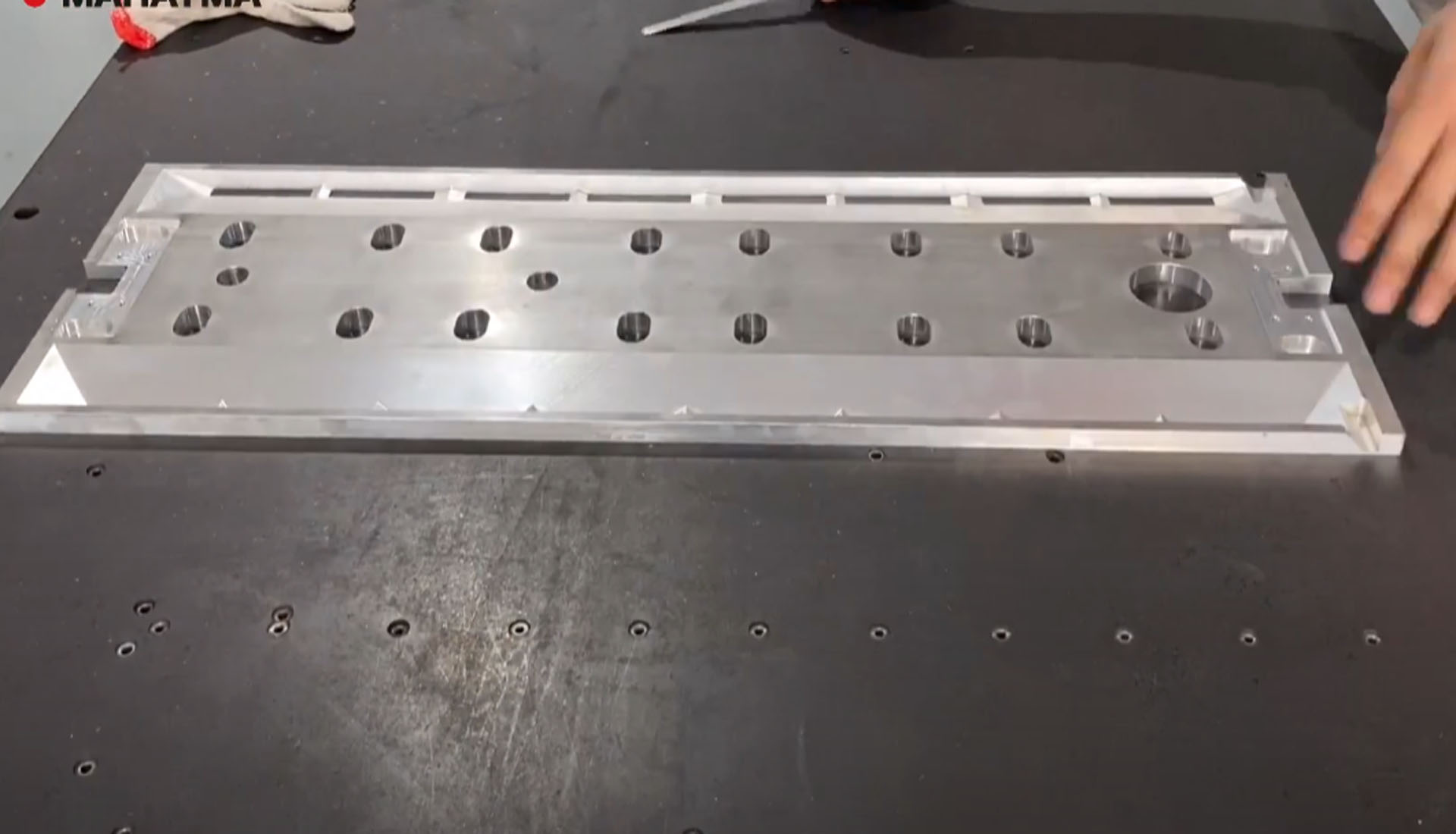

CNC machining is a process that involves the use of computer-controlled machines to remove material from a workpiece, resulting in a final product with precise dimensions and smooth surface finishes. With the advent of high precision aluminum plate CNC machining, manufacturers can now produce aluminum plates with unparalleled accuracy and repeatability.

The key to high precision aluminum plate CNC machining lies in the advanced software and hardware components that control the machining process. The software allows the operator to create a detailed computer-aided design (CAD) model of the desired aluminum plate, specifying the dimensions, tolerances, and surface finishes. The CAD model is then converted into a set of instructions that the CNC machine follows to produce the final product.

One of the main advantages of high precision aluminum plate CNC machining is its ability to achieve tight tolerances. Tolerances refer to the allowable deviation from the desired dimensions of a part. Traditional manufacturing methods often struggle to meet tight tolerance requirements, leading to inconsistencies and inaccuracies in the final product. However, CNC machining can consistently produce aluminum plates with tolerances as low as ±0.001 inches, ensuring a high level of precision and uniformity.

Another advantage of high precision aluminum plate CNC machining is its versatility. CNC machines can perform a wide range of operations, such as milling, drilling, tapping, and turning, all with a single setup. This eliminates the need for multiple machines or manual labor, streamlining the production process and reducing costs. Additionally, CNC machines can easily accommodate complex shapes and intricate designs, allowing for greater design freedom and customization options.

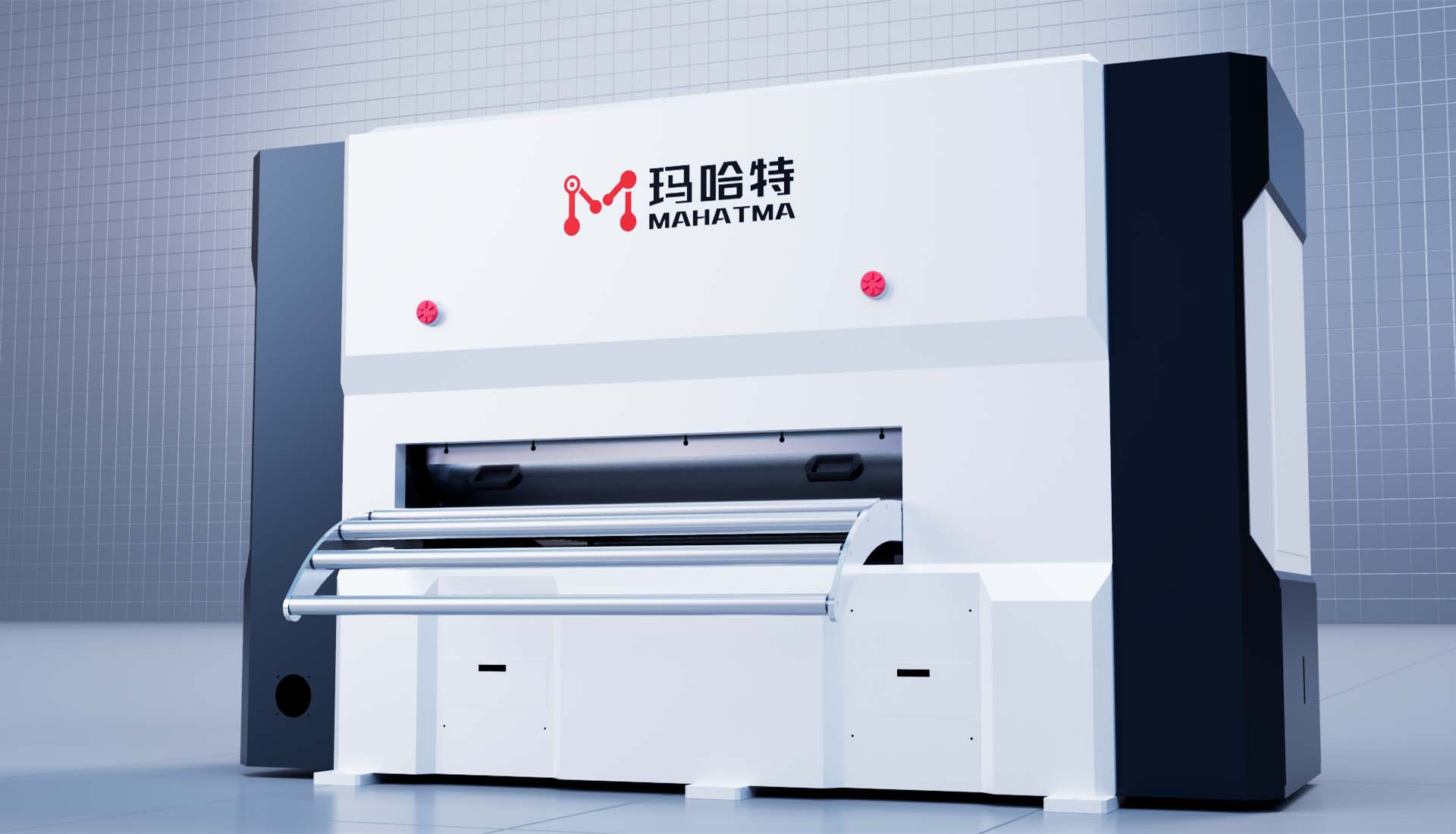

In addition to its precision and versatility, high precision aluminum plate CNC machining also offers improved efficiency and productivity. The automated nature of CNC machines allows for faster production times and increased throughput. Moreover, CNC machines can operate continuously, reducing downtime and maximizing productivity. This makes high precision aluminum plate CNC machining an ideal choice for high-volume production runs.

Furthermore, high precision aluminum plate CNC machining ensures consistent quality and reliability. The use of CNC leveling machines eliminates the potential for human error and ensures that each aluminum plate produced meets the exact specifications of the CAD model. This results in a higher level of product consistency, reducing the risk of defects and ensuring customer satisfaction.

In conclusion, high precision aluminum plate CNC machining is a cutting-edge manufacturing process that offers numerous advantages over traditional manufacturing methods. Its ability to achieve tight tolerances, versatility, improved efficiency, and consistent quality make it an ideal choice for producing high-quality aluminum plates. As technology continues to advance, high precision aluminum plate CNC machining is expected to become even more prevalent in various industries, further revolutionizing the way aluminum plates are manufactured.