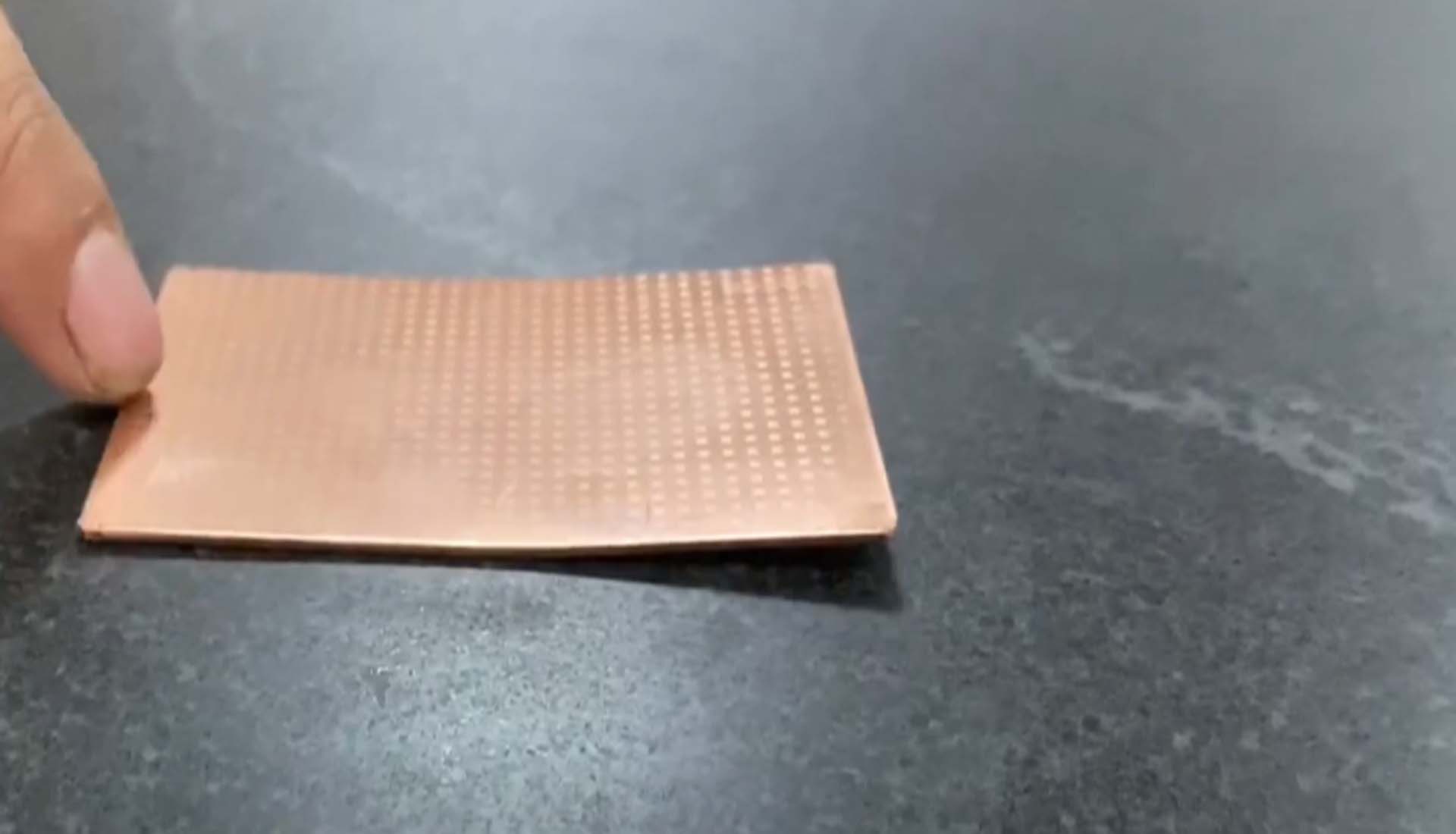

High precision thin copper sheet leveling processing is a process for processing thin copper sheets, mainly to ensure a smooth and flat surface and achieve certain accuracy requirements. This process is generally used for manufacturing electronic components, Optical instrument, precision Machine element and other fields.

The specific processing steps are as follows:

1. Preparation: Place the thin copper sheet into the processing equipment and perform surface cleaning and rust removal treatment.

2. Leveling processing: The thin copper sheet is leveled through rollers or pressure rollers to make its surface smooth and flat, and achieve certain accuracy requirements. During the processing process, it is necessary to make precise adjustments and controls to the processing equipment to ensure machining accuracy.

3. Inspection: Inspect the processed thin copper sheet to confirm whether its surface flatness and accuracy meet the requirements. If there are problems, rework or correction is required.

4. Subsequent treatment: Conduct subsequent treatment on the processed thin copper sheet, such as coating, cutting, bending, etc., to meet specific application requirements.

High-precision thin copper sheet leveling processing is a complex process that requires experienced technical personnel and high-precision processing equipment to achieve good processing results.